|

Product Video:

|

|||||||||

|

|

||||||||

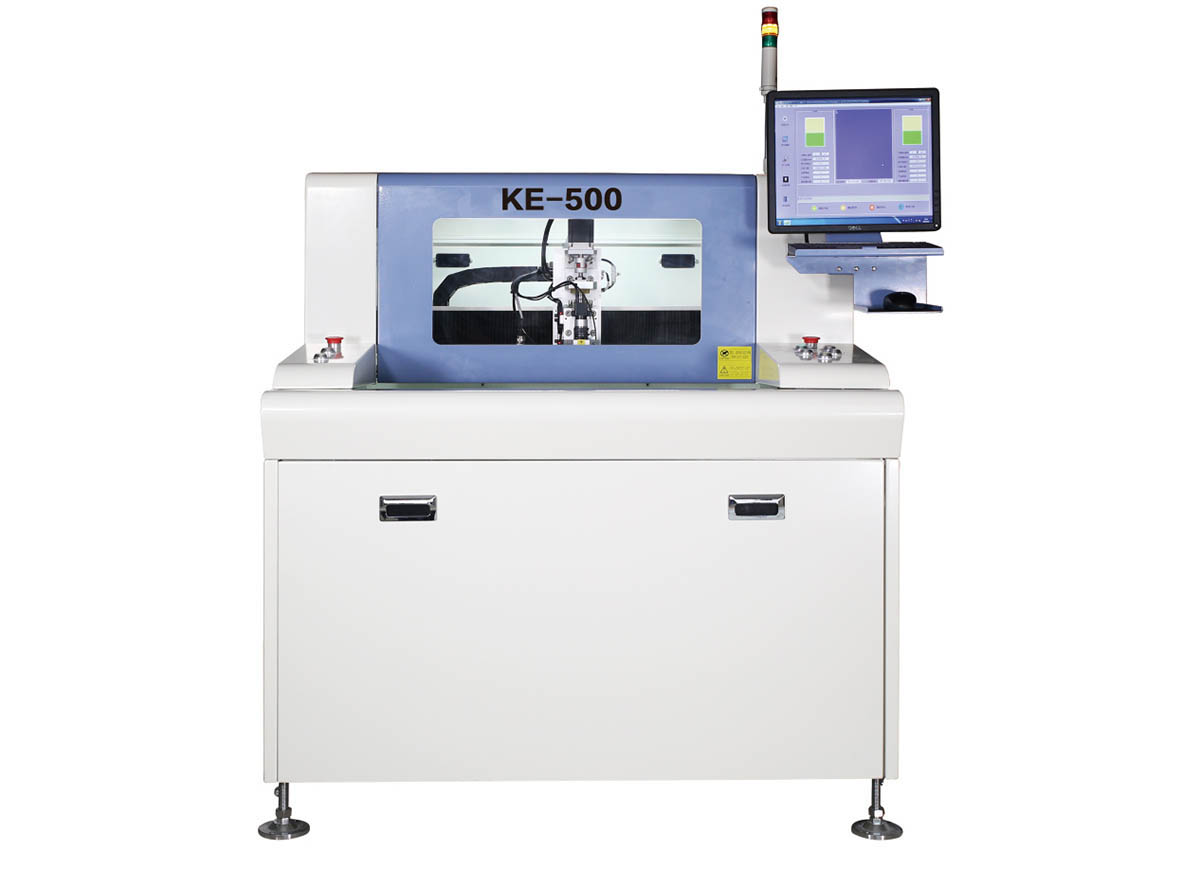

The KE-500 series splitter is a device that uses a milling cutter to run at high speed and four-axis servo linkage to split the multi-piece PCB into pre-programmed paths. It replaces the cutting defects caused by manual breaking, V-CUT or PUSH, thereby improving product quality and reducing scrap rate. This equipment uses AC servo motor, WIN7 system, through high-pixel CCD to make programs, teach, edit the cutting path, and can be modified and simulated in one step. The work platform uses two servo exchange moves, which can effectively reduce the machine idle time, thus achieving higher production efficiency and quality.

| High speed spindle The imported high-speed spindle adopts the German SycoTec (Kavo) spindle motor widely used in the industry's high-end splitting machine. The spindle has high speed (60,000 rpm/min), long service life, convenient loading and unloading, smooth cutting surface without burrs and flawless. And with the original SycoTec 4426 spindle inverter, the spindle motor has a longer service life, higher cutting force distance and the lowest temperature rise effect. |

| Dual servo platform Using servo to drive two working platforms, alternately processing and placing PCB substrates, reducing waiting time, increasing production capacity, and solving the accuracy problem of the cylinder-driven platform. |

| visual system High-pixel color CCD and large-magnification lens for program teaching and editing simulation. The automatic MARK positioning correction system improves the cutting precision, prevents the board from being missed and cuts the substrate, and the left and right program copying and switching models are faster. Optional bar code reading function, to achieve 1D/2D bar code reading and save or upload, easy to track and digital management. |

|

Vacuuming method Exclusive built-in vacuum, the fifth generation design makes the overall effect of the equipment beautiful and simple space, beautify the overall effect of the workshop, flexible movement, convenient placement and maintenance. Shorten the vacuum path to improve the vacuuming effect, good sealing and low noise. Dust bag can be cleaned and reused to reduce production costs |

| Broken knife and knife detection During processing, it is possible to set whether each step of the test or each PCBA test tool is broken or slipped to prevent PCBA damage due to tool slippage. |